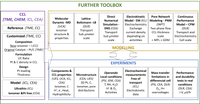

Methodology

Electron microscopy (CEA): includes several state of the art equipment, SEM, FIB-SEM and TEM, allowing MEA microstructure investigation at different scales. Various associated techniques are available such as X-EDS that allows a local chemical analysis or electron tomography that provide 3D images of the microstructure.

Limiting Current Analysis – LCA (DLR, CEA, PSI): LCA is a method to determine transport resistance through the cathode structure of a fuel cell. However, high current densities operation of next-generation MEAs requires not only excellent oxygen transport properties at the cathode, but also of proton transport in the CCL. Therefore, the proton transport and oxygen transport phenomena will be discriminated and quantified by performing specific fuel cell experiments in the so called hydrogen pump mode and by limiting current measurements, respectively.

Dynamic Vapor Sorption – DVS (ICL, UCA, CEA): It allows the water adsorption isotherms of components of the CL to be determined. This the wetting performance and degree of liquid water in equilibrium with gas at different RH values and temperature. Hysteresis and time dependence of processes can be studied as the surface energy energy by using liquids other than water.

Neutron Imaging – NI (PSI) is a powerful tool to characterize water distribution in PEMFC, since it is fully non-intrusive, and allows visualization of very small amount of water even behind dense materials and complex instrumentation. While analysis of the water content in the CL might still be out of reach, NI will definitely allow for determining the MPL’s content being much thicker.

Differential Cell – DC (CEA, DLR) is a fuel cell setup designed to ensure homogeneous Operation of the MEA from inlet to outlet of the MEA. Electrochemical measurements such as PGA, EIS and LCA will be conducted in this setup to simplify the analysis of the results and to be able to compare them with simulations. Performance/durability tests (DLR, CEA) will be conducted in 25 cm² single cell with protocols developed by the

Atomic Force Microscopy - AFM (UES, UCA) combines many different techniques to analyse fuel cell components, and especially CCL structure with high resolution on a nm scale close to operational conditions. These are namely topography, mechanical properties, ionic and electronic conductivity, thermal conductivity and surface potential. In combination with a bipotentiostat local electrochemical behavior, like oxygen reduction at the catalyst layers or studies at model electrodes can be performed.

Electrochemical Impedance Spectroscopy – EIS (CEA, DLR): It is an electrochemical technique aiming at dissociating the contribution of the phenomena to the total impedance of the cell. Effective proton resistance of CCL, ohmic resistance of the MEA and effective diffusion coefficient of the MEA/CCL can be extracted by fitting data with models from literature.

Small Angle Scattering - SAS (CEA) is the probe of choice to characterize the nanostructure of the ionomer which is uniquely related to its water content, and water activity. AX-Ray microfocus synchrotron beamline will be used to to study Operando the ionomer within the CCL to extract local water activity and liquid water content in case of condensation.

Pulsed Gas Analysis – PGA (PSI) involves three techniques aiming at characterizing limitations due to kinetic of ORR or O2 transport limitations during operation. One technique will provide measurements of concentration performance limitations due to molecular diffusion limitations on one hand and of limitations due to Knudsen diffusion and diffusion of O2 into ionomer films around platinum particles on the other hand. Another will allow measurement of the O2 diffusion resistances directly. The last one will allow investigation of the ORR kinetics.

µ-Raman (IEM) represents a remote, non-contact method for monitoring the water content within the membrane and the CL temperature during operation by thermography.

Floating Electrode – FE (ICL) is an electrochemical setup which will be used for intrinsic studies of supported Pt catalysts for ORR, e.g. with reduced transport limitations of O2 and proton transport issues. Measurements will be done in-situ in conditions as close as possible to Operando conditions.

Electrokinetic Model – EM (ICL) is analytical and will be improved by incorporating site blocking on the catalysts along the lines of previous work. These will be parameterised with the fewest physically relevant variables needed in order to match the experimental results determined in the FE experiments.

Fully atomistic Molecular Dynamics modelling of ionomer thin films – MD (UCA) will be developed to investigate the influence of material set (ionomer, catalyst, catalyst support) and operational conditions (humidity, temperature) on O2 and water diffusivity through the bulk of the ionomer film and the related interfacial mass ‘transfer’ coefficients at gas/ionomer interface. The self-assembly process of ionomer film formation on Pt/C catalyst aggregate will also be simulated and compared with structures obtained via CL characterization platform.

Direct Numerical Simulation at the nanometer scale - DNS (CEA) is a Finite Element Method taking into account the real structure of the CCL to compute proton, O2 transport and heat transports coupled with electrochemistry.

Lattice Boltzmann Modelling at the sub-micrometer scale - LBM (DLR) will be developed to investigate the transport of oxygen and protons in the CL on the sub-micrometer scale. These simulations will provide insight on the effect of the microstructure (ionomer distribution, porosity of the carbon, etc.) on the transport limitations and allow for suggestions of improved microstructures. Effective coefficients will be derived from the LBM for the upscaling to the continuum single cell model.

Pore Network Modeling at the CCL scale – PNM (INPT) aims at computing various transports coupled with the electrochemical reactions at the scale of the whole thickness of the CCL and typically at the rib-channel scale in terms of in-plane extension. The second objective is to develop PNM simulations at the representative elementary volume scale for computing effective properties, in particular two-phase flow related properties such as the capillary pressure curve and the relative permeability curves (for various scenarios of mixed wettability).

Continuous Performance Model at the cell scale - CPM (DLR) will incorporate sub-models from upscaling of LB and PNM. Simulations of cell performance (polarization curves and impedances) will be performed and the model will be validated with dedicated experiments on differential cells. Finally, the model will be used to determine the contribution of the different transport losses to the overall cell performance.